1. EXECUTIVE SUMMARY / ABSTRACT

Per customer contract, Nova Integration Solutions (NIS) shall design a MIL-SPEC Inkjet printer capable of printing at -40°C while drawing under 200W in total power and must print within a 30 minute time frame.

Inherently Inkjet printers are susceptible to freezing temperatures due to liquid ink and commercial grade components generally not rated for low temperatures. The printer used for the Model 1151 is the HP 6230 which has an operating temperature range of +5°C to +40°C.

Framework

This document will further detail the problem in the following section. Program background and a brief education on MIL-STD-810G will follow. Our final solution will be detailed while introducing test data which will be summarized in a brief conclusion,

Objectives

- Demonstrate compliance with MIL-STD-810G Operating Temperature requirement for class 2 cold temperatures

- Demonstrate compliance with customer requirement of printing within 30 minutes after being stored in -40°C ambient temperature

2. PROBLEM

The customer requirement mandates that the Model 1151 Inkjet printer must (1) operate at -40°C ambient temperature per MIL-STD-810G and also (2) must become fully functional within 30 minutes of a storage condition in which the ambient temperature is -40°C.

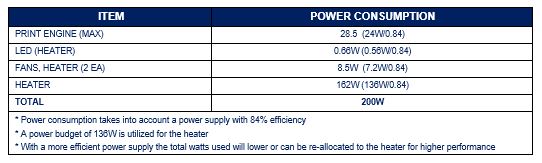

Power Budget

The design has a restriction of 200W of power draw with a power input of 18-32VDC. Internally, the Model 1151 utilizes a DC-DC converter power supply which can accept inputs of 18-32VDC and outputs a constant 32VDC which powers the print engine and heater circuit. The heater is powered by this converter, rather than the input power, to maintain the full heating capabilities of the heater assembly.

Initial Testing

Using the standard 100W heater provided by NIS test were conducted as a baseline to see where improvement was needed. With the current design, the printer was able to meet the MIL-STD-810G operating temperature specification but only down to -20°C but was not capable of overcoming the full -40°C requirement. With this knowledge, the printer would not be able to meet the customer specification to become functional within 30 minutes.

Evaluated Improvements

With further evaluation and test, the following improvements were deemed necessary to facilitate passing of these two test:

- Increased heater wattage

- Direct heating of critical print engine components

- Upgrade other electronics to those suitable for -40°C operation (to limit the required heating area)

- Mitigate effects of condensation

- Evaluate the potential of using an insulating coating to keep cold out and/or heat in

3. BACKGROUND

3.1 Inkjet printers and cold weather

The printer industry has made many advances in the quality and the features offered in printers. Inkjet printers remain a top choice for home and business alike due to their low price and high availability of ink and paper. However, one weakness of inkjet printers is printing in cold weather environments. They are designed to work in comfortable temperature environments like offices and homes, not artic environments.

With inkjet printers, it is difficult to print in cold weather due to the freezing of the ink. While the exact freezing temperature is not published, it seems that printer ink starts to freeze close to -5°C for some models, which is below freezing of water due to additives such as glycol, isopropyl alcohol, and glycerin. If it doesn’t freeze at cold temperatures, it could still be unusable due to separation of the additives. And if it does freeze, you could see physical damage of the ink cartridge and printer due to expansion of the ink, causing cracking or bursting of the ink case.

3.2 What is cold weather?

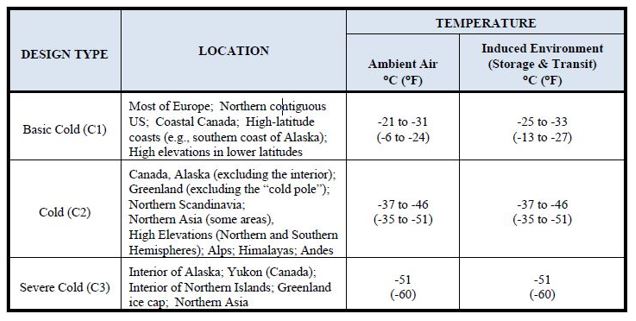

According to MIL-STD-810G, method 502.5, Table 502.5-I, cold weather temperatures are defined in three classes. Class 1 is Basic Cold with a range of -21°C to -31°C (-6°F to -24°F). Class 2 is Cold with a range of -37°C to -46°C (-35°F to -51°F), and Class 3 is Severe Cold with a temperature down to -51°C (-60°F).

For this exercise, the intention is to print in class 2 cold environments, specifically down to -40°C.

MIL-STD-810G Table 502.5-I

4. SOLUTION

The solution to these problems required a design update consisting of the following items. In summary, the goal was to increase the heater power, direct the heating to critical components, and to reduce the total air volume requiring heating.

4.1 Direct heating of critical print engine components

The first step in designing a heating system that will overcome class 2 cold temperatures is to determine the weaknesses of the printer at these temperatures. With iterative testing NIS was able to confirm its findings that certain components would survive -40°C while others began to fail shortly after reaching the freezing temperature range. In short, the updated design focused heating on the components requiring temperatures to be maintained in a positive range. This was accomplished with an updated heater design utilizing “closed loop” circulation and baffling which helped keep cold air out and hot air in.

4.2Increased Heater Wattage

With the power budget in mind, NIS increased the heater wattage from 100W to 140W.

Note: The power budget states a limit of 136W for the heater with the current power supply at 84% efficiency. The opportunity is available to increase the performance of the PSU or slightly decrease the heater wattage. For this discussion either approach will be acceptable.

4.3 Mitigate Condensation

It is well known that rapidly heating air has the potential to cause condensation and standing water which can cause critical damage to electronics. Further, for printers it can cause paper to wrinkle, curl, or increase in weight which will cause paper jams or printer mechanisms problems when cycling the paper. The updated design addresses these issues in critical areas.

4.4 Upgrade Electronics

The opportunity existed to upgrade certain components to those that would be operational at -40°C. This provided dual benefits of having more reliable components and also decreasing the air volume needing heated air.

4.5 Insulating Coatings

After very thorough review of many types of insulations and there strengths/weaknesses as it pertains to military applications, it was determined insulation is not necessary to meet the current objectives. An opportunity does exist to potentially lower the heater wattage with the use of ceramic/epoxy based insulations. For the intentions of this document it can be assumed that insulation is an option, but not required or used for the test mentioned herein.

5 TESTING RESULTS

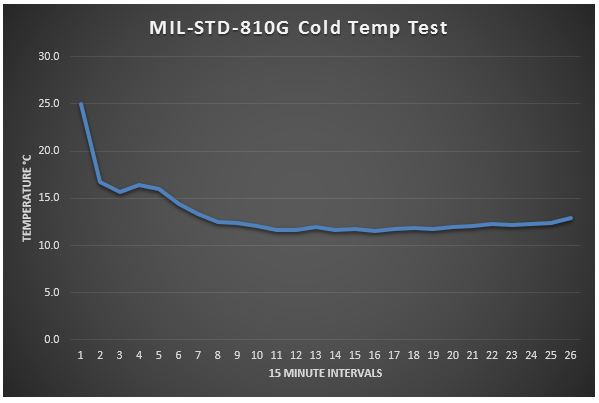

5.1 MIL-STD-810G Operational Temperature Test

For maintaining temperature, MIL-STD-810G operational temperature test following MIL-STD-810G, Method 502.5, Procedure II was run for 6 hours and 15 minutes. Starting at an ambient temperature of 25°C the chamber was dropped and maintained at -40°C for the remaining duration of the test. The printer and heater assembly remained operational throughout the entire test. The chamber temperature, chassis internal temperature, and print engine internal temperature were monitored throughout the testing cycle.

The chart below shows the print engine internal temperature which never dropped below +11.5°C. At this temperature the print engine remains fully functional and completely stable for an unlimited amount of time.

To verify functionality a test print was initiated from the control panel. An acceptable test print is fully legible with all four colors shown without error.

5.2 30 Minute Storage to Print Test

To validate meeting the customer specification of 30 minutes to printing from a storage condition NIS must conduct a custom test not following a specific MIL-STD-810G section.

For this test, the non-operational printer was placed in the thermal chamber and was set to -40°C to allow the printer to soak for 22 hours. The printer and heater remained powered OFF during this entire duration. Like the previous test, the chamber temperature, chassis internal temperature, and print engine internal temperature were monitored throughout the testing cycle.

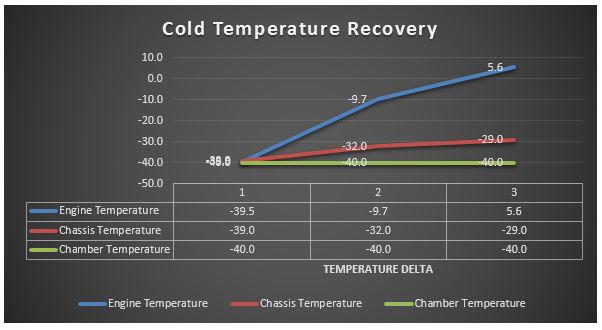

After -40°C was confirmed in the chamber, chassis internal and print engine internal temperature the printer and heater were powered on and monitored for the next 30 minutes. Temperatures were monitored during this time period as represented in the chart below.

The chart below shows the print engine internal temperature reach +5.6°C at the 30 minute mark. To verify functionality a test print was initiated at this 30 minute mark from the control panel. An acceptable test print is fully legible with all four colors shown without error.

This test verifies the print engine can recover from a -40°C storage condition within 30 minutes.

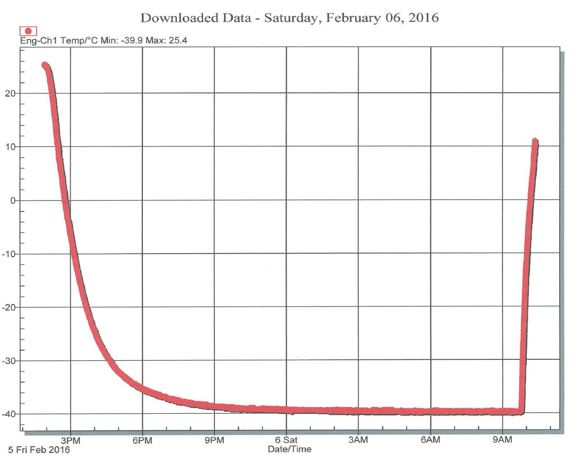

The next chart is supplemental data showing the internal print engine temperature during the 22 hour soaking cycle. Note that the starting temperature is ambient temperature of approximate +26°C. After approximately 1 hour the print engine is below the 0°C freezing temperature. At hour 8 through 22 (14 hours total) the printer is maintaining a -40°C temperature before the printer and heater are turned on. Within a 30 minute time period the print engine increases in temperature from -40°C to +5°C representing a +45°C temperature rise.

6. CONCLUSION

Per customer contract, Nova Integration Solutions (NIS) was tasked with designing a MIL-SPEC Inkjet printer capable of printing at -40°C from an operational and be capable of printing after a storage condition within 30 minutes. This is while drawing under 200W in total power.

With the necessary design improvements in place NIS was able to accomplish both objectives:

- Demonstrate compliance with MIL-STD-810G Operating Temperature requirement for class 2 cold temperatures

- Demonstrate compliance with customer requirement of printing within 30 minutes after being stored in -40°C ambient temperature

NIS specializes in the ruggedization of commercial electronics which is demonstrated by the Rugged and MIL-SPEC printer line offered. Military applications present many challenging environments for these commercial electronics which can be overcome by proprietary processes and the staffs design expertise in this particular field.