Before new products are released, they are subject to a thorough Design Validation & Test (DVT) plan verifying environmental performance levels and the product’s functional characteristics. An Acceptance Test Procedure (ATP), a subset of the DVT, is then written to insure that each production model meets specifications and is defect-free prior to shipment. A typical DVT plan consists of many recognized industry and military specifications. Many of which are listed below.

Environmental Testing

- RTCA DO-160D (Shock, Vibration, Temperature, Humidity, Altitude).

- MIL-STD-810F (Shock, Vibration, Temperature, Humidity, Altitude).

- MIL-STD-461E (EMI).

- MIL-STD-901D / 167-1 (Shock, Vibration).

- MIL-STD-704F / 1399 (Power).

- MIL-STD-1686C (ESD).

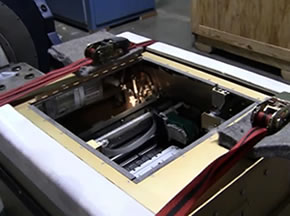

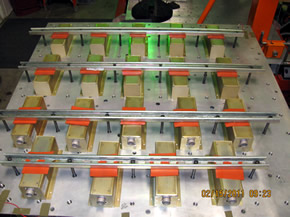

In-House Capabilities

The following in-house test capabilities exist within the divisions of TDI:

- Thermal

- Vibration

- Shock

- Electrical

- Functional