Shock trays of all types are designed and manufactured by NIS. They are used when blind mating and shock isolation requirements exist in support of enclosures installed in ground mobile vehicles, naval vessels, military shelters and on aircraft. These applications (typically MIL spec ATRs) require the use of heavy materials and are sized with shock isolators of varying types insulating the enclosure from harm due to shock conditions.

The trays use heavy structural metal materials (typically aluminum), or as a hybrid together with carbon fiber in support of a lighter weight solution. They are customized to accommodate limited space constraints, and must consider size, weight and loading to include sway as a result of a dynamic shock condition.

Shock trays are specially engineered and are highly application specific. The enclosure together with the shock tray is modeled using the 3D SolidWorks Tool set. Simulations are then run by in-house Finite Element Analysis (FEA) personnel to eliminate guesswork and to verify compliance to the specifications.

Coil or Shock Isolators

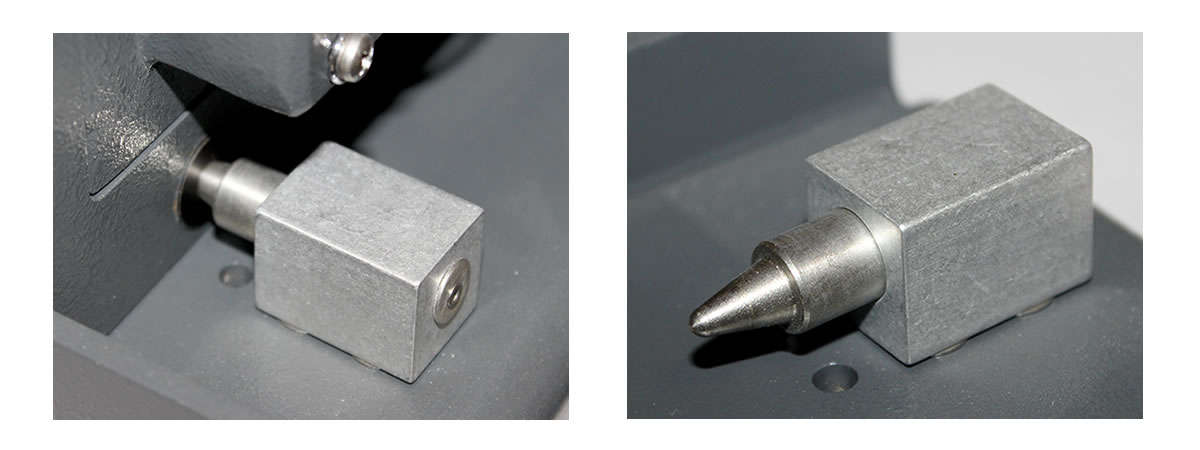

Spring-Loaded Gide pin

Features:

- ARINC 404A and 606 compliance

- Custom and all standard ATR lengths and widths

- Metal (aluminum) or combined with light-weight carbon fiber materials

- Spring loaded standard and custom guide pin spacing

- Wire rope cable and shock isolator mounting

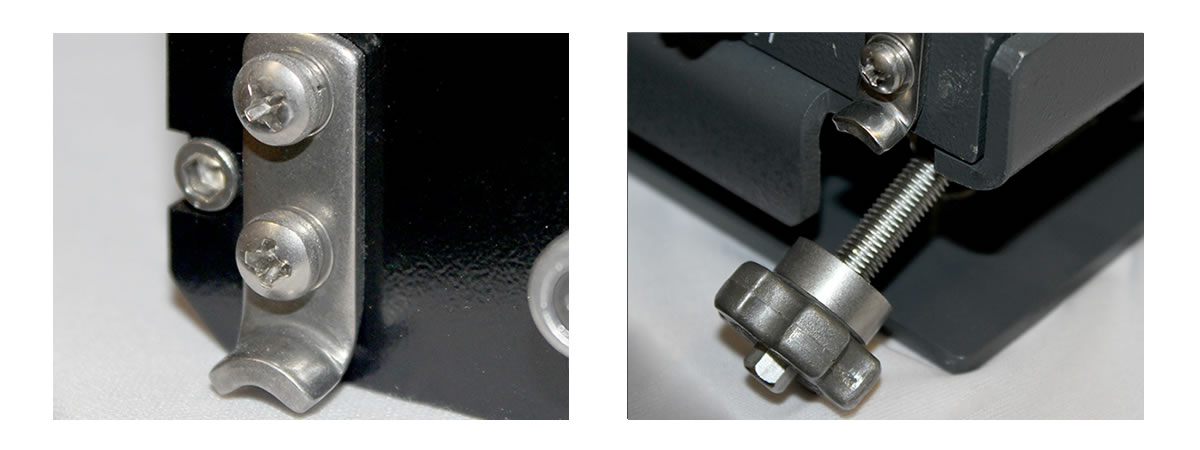

- Standard torque limiting, self-locking and thumb-screw hold downs

- Multiple sized J-hooks